Securely and safely fixing components to the concrete substrate requires fixings with the highest load-bearing capacity and resistance to environmental conditions. One of the solutions are mechanical express anchors, which find their application in installations where medium and heavy loads are involved. Wiktor Paradny, an expert from Klimas Wkręt-met, suggests what to pay attention to and what mistakes to avoid when using anchors.

Mechanical anchors, otherwise known as express anchors or segmental anchors, are the unseen silent hero of any building structure. Medium and heavy duty anchors are used to fix the most important structural elements in a building, such as mullion and transom glass facades, ventilated facades, balcony railings, staircases or steel structures. The durability of the aforementioned elements depends, among other things, on the correct installation and selection of the anchor – the anchor arrangement developed in the design documentation.

The design must meet the standards described in the Eurocodes, the design guidelines, and the contractor should carry out the installation in accordance with the principles contained in the European Technical Assessments (ETA) and the design assumptions. Only then can we speak of a safe connection.

In my 10-year career in fastening systems and almost 20 years of working in the construction industry, I have repeatedly encountered blatant disregard for safety rules and violations of good construction practices. That is why we have placed a very strong emphasis on the education of our cooperating partners. We conduct many training courses and workshops on the correct and safe execution of anchor connections using Klimas Screw-met systems. Our contractors know why it is important to use products of the highest quality, why it is important to use certified products that meet the highest European guidelines, as in the case of LE anchors with European Technical Assessment approval – ETA – says Wiktor Paradny, an expert from Klimas Wkręt-met.

Which design mistakes should be avoided?

The European Technical Assessment (ETA) gives the characteristic forces for a single anchor without the influence of the concrete edge and the spacing between anchors. Structural static calculation programs can quickly calculate what force at a given load occurs in the single most heavily loaded anchor for a designed fixing console with two or more anchors in a system. Comparison of this force only with the characteristic force given in the ETA is not sufficient. A separate calculation (according to Eurocode 2EN 1992-4:2018) must be carried out, including the geometry of the fixing console, distances between anchors, concrete edge distances and occurring loads in the console, such as pull-out, shear and bending moments. All possible failure patterns of the connection and their interactions should also be checked.

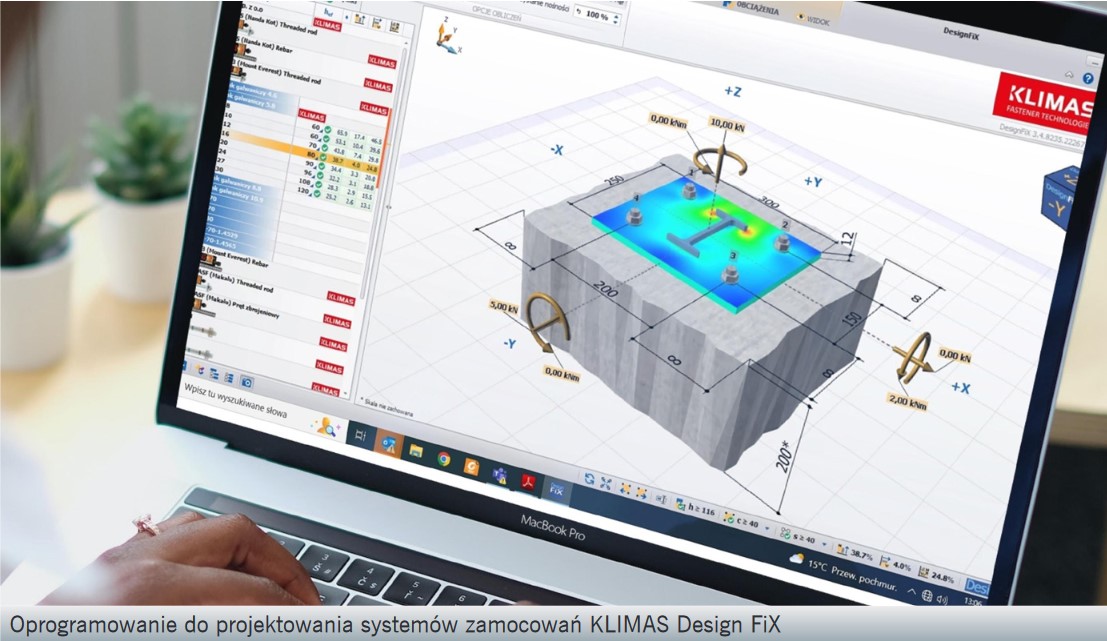

Failure to follow design guidelines can lead to weakened anchorage strength and inadequate anchor performance, which can compromise the safety of the structure. Therefore, it is important that the anchorage design is carried out by a specialist or dedicated software, such as Klimas DesignFiX, which will take into account all factors affecting the correct performance of the anchors and adapt them to the specific working conditions. The software can be downloaded free of charge from the DesignFiX website.

Which installation errors should be avoided?

Even the best-designed anchorage can fail if the rules of correct installation are not followed. The most common installation errors include: an incorrectly drilled hole – an incorrect hole diameter, a hole that is too shallow or the wrong angle to drill the hole. Another mistake is skipping the stage of cleaning the holes from the dust left after drilling. The dust left behind can weaken the anchor’s connection to the concrete by up to ~40% of its load-bearing capacity. The last important step of installation is to use a torque spanner and tightening the anchor to the correct Tinst torque specified in the ETA for each diameter. Using a regular spanner will either lead to the clip being pulled through the anchor or the anchor being under-tightened. Each of our anchor packs contains detailed installation instructions that should be used by the user.

During installation, we must not forget to maintain the minimum distances of the anchor from the edge of the concrete. The minimum distances determined in the design are specified in the ETA and given in the Klimas DesignFiX software report.

What to consider when choosing an anchor?

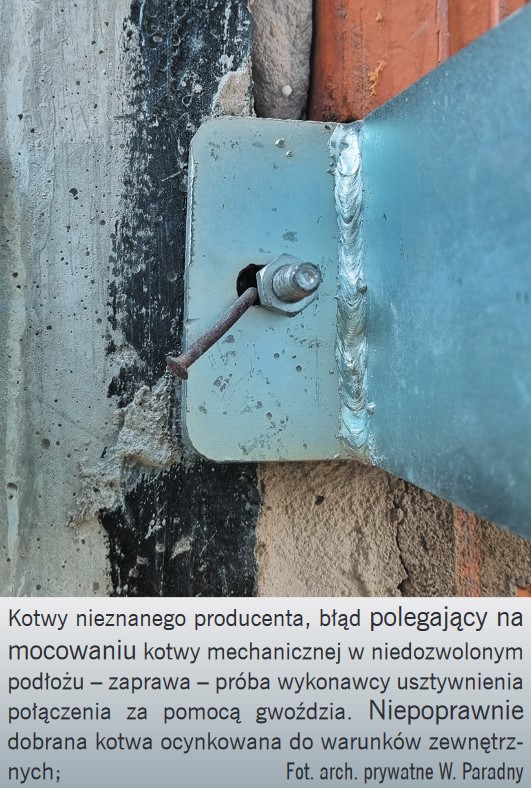

According to the ETA, the use of galvanised anchors in aggressive external conditions is not permitted. In external conditions C4 (also under polystyrene, ventilated façade, mullion and transom etc.) an acid resistant A4 stainless anchor must be used, which has a service life of 50 years. An exception can be hot-dip galvanised or aluzinc coating, which has a shorter service life (up to 15 years) in corrosivity class C4. These types of solutions are suitable for structures with a short temporary life, such as carports.

Attention should also be paid to steel connections. We should not combine, for example, aluminium or stainless steel construction with galvanised anchors. A galvanised anchor has a weaker potential than stainless steel or aluminium alloy, and if a galvanised connection occurs, there will be accelerated corrosion of the red galvanised anchor, which will weaken the connection. In such cases, a LE-A4 acid resistant stainless steel anchor should be used.

Anchor selection should meet the design requirements and all certifications along with the parameters for the project. Cheap anchors, imitating the appearance of professional anchors, are: low performance steel grade 4.8 (steel grade 5.8 is standard), low strength parameters, high displacement in the hole under load, low quality nuts and washers, low corrosion resistance due to minimum thickness of zinc coating.

Klimas Wkręt-met, present on the Polish construction market for more than thirty years, has made a significant contribution to the development of the entire sector. Experts are actively working on the evolution of the various groups of mechanical fastening systems in line with international and national requirements. The DNA of KLIMAS is reflected in the slogan POWERFUL FOR Generations, which carries family values such as trust, peace of mind, protection and safety. These guide all the company’s activities, including production.